Recent Development in Pharmaceutical 3D Printing: A Bird’s Eye Perspective

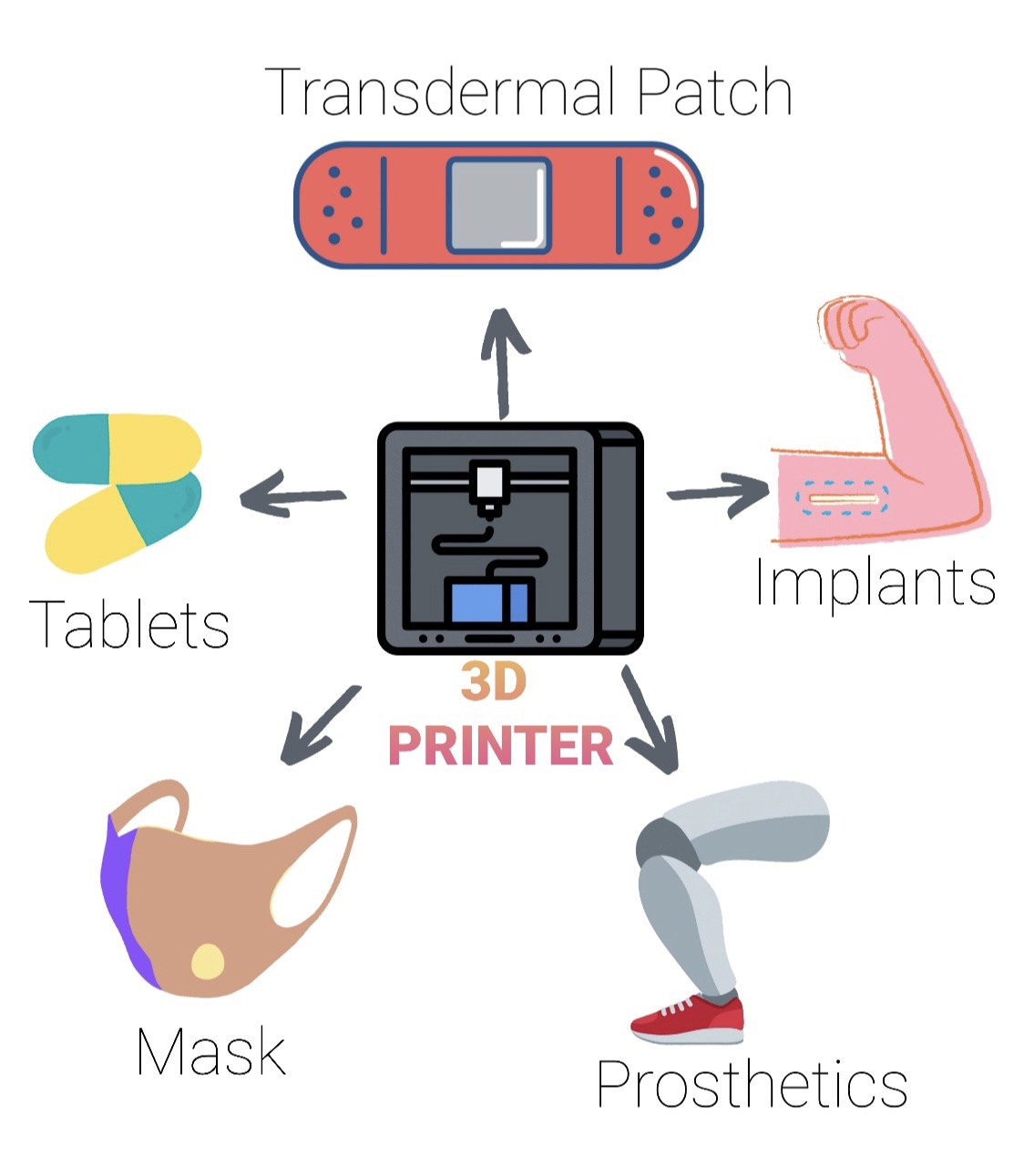

Pharmaceutical product development is constantly witnessing advancements in the creation of novel delivery methods in order to enhance medication therapeutic effectiveness. Furthermore, 3D printing (3DP) has been utilized to produce medication delivery systems and biomedical equipment, resulting in a paradigm change in the healthcare sector.

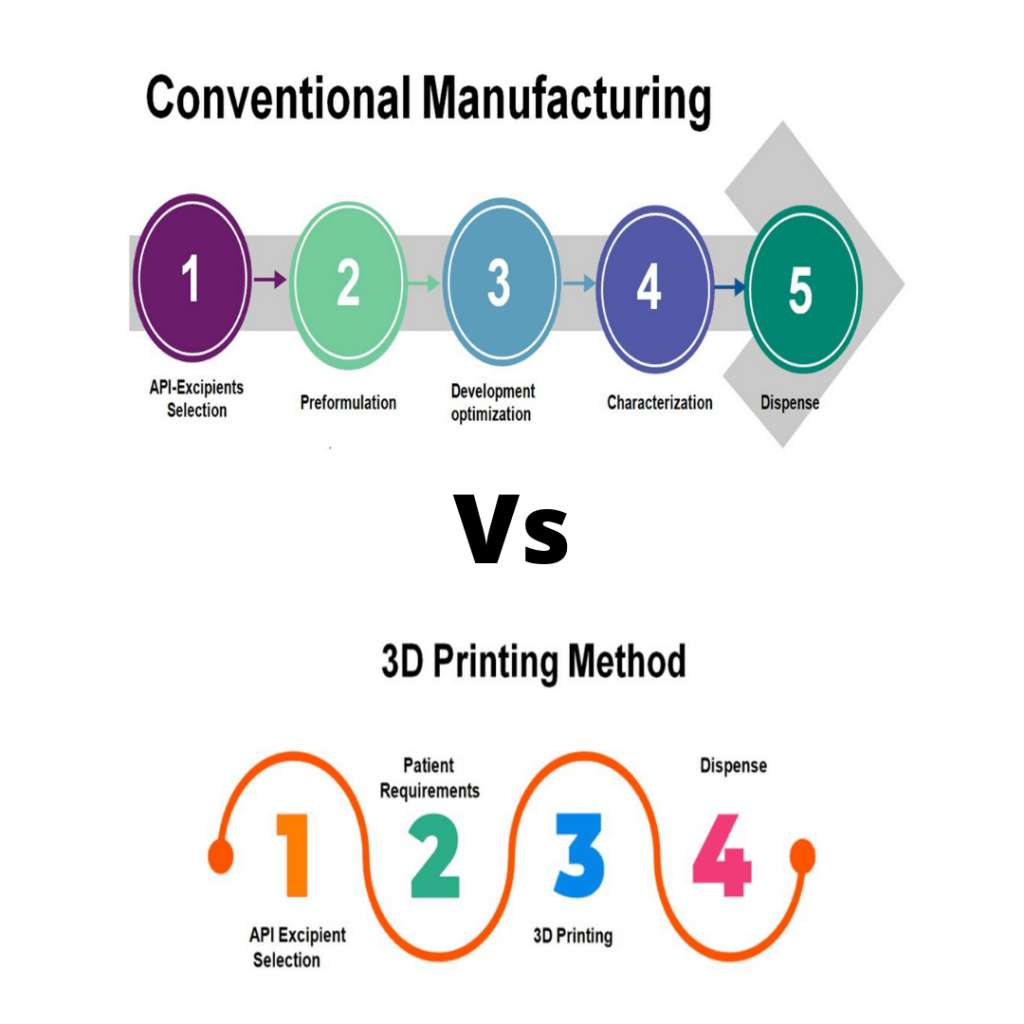

For batch production, traditional manufacturing typically requires the comprehensive optimization of many ingredients, while additive manufacturing does not need the previous optimization of the formula or amount of components. Despite the fact that machinery has evolved, the production method has remained largely same and is still dependent on the compression of powders and granules. Traditional manufacturing is time, resource, and effort intensive, while 3DP is extremely efficient and cost-effective in terms of time, resource, and effort. Furthermore, instead of a population-centric strategy, customized 3DP technologies allow the fast design and development of tailored medication treatment for specific patients.

Figure 1: Key difference between conventional and 3D Printing

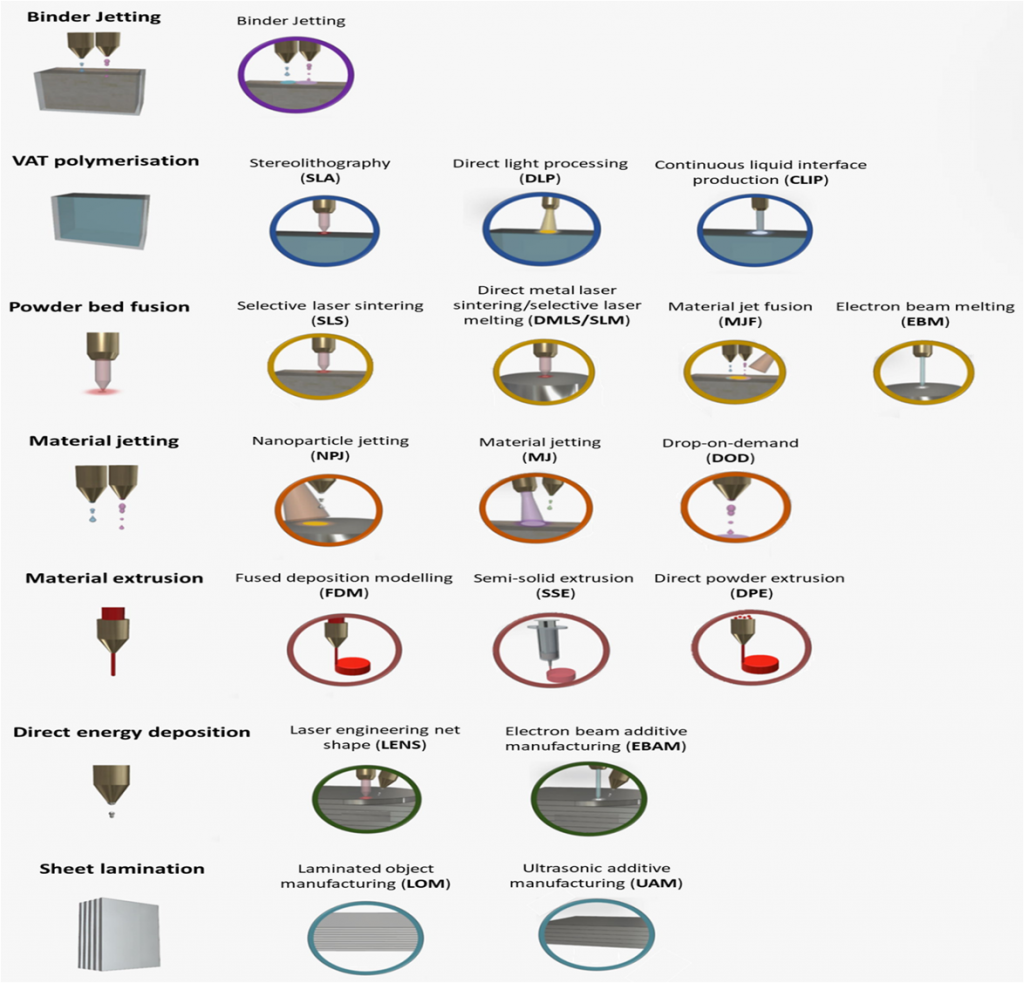

Figure 1: Key difference between conventional and 3D PrintingFor medication delivery and biological purposes, a number of 3D-printing methods have been developed. Binder jet printing (BJP), fused deposition modeling (FDM), semi-solid extrusion (SSE), selective laser sintering (SLS), and stereolithography (SLA) are some of the most significant methods. We’ll give you a quick rundown of these methods in figure 2.

Figure 2: 3D Printing techniques [1]

Figure 2: 3D Printing techniques [1]Recent Advances

3D Printed Polypills

The term “polypill” refers to a single tablet that includes a mixture of multiple medicines, possibly improving patient adherence for individuals who take a variety of pills. It also enables for the customization of a particular medication combination or drug release to meet the requirements of the person [2]. This is especially beneficial in polymedicated individuals, such as the elderly patient with multiple disease. Genina et al. created an oral dual-compartmental dose unit combining rifampicin and isoniazid in order to physically separate and regulate the release profile of this anti-tuberculosis medication combination. The team created the unit in two steps with the assistance of computer-aided design.

Combining 3D Printing and Machine learning in Pharmaceuticals

By generating accurate and timely predictions for key process parameters and formulation properties of drug-loaded products, ML has the potential to reduce costs and simplify the 3DP process. The combination of ML and 3DP, both of which are digitalized processes, may ease the shift from one-size-fits-all therapies to data-driven omics and the production of customised medications [3]. Together, 3DP and Machine learning can use human-learning intelligence to expedite medicinal product development, guarantee strict quality control (QC), and inspire novel dosage-form design. Machine learning skills may usher in a new age of customized treatment with simplified 3DP medication delivery.

Selective Laser Sintering (SLS) for converting crystalline drugs to amorphous and improving solubility and bioavailability

A large number of compounds identified in the pharmaceutical drug discovery and lead optimization process are known to be rejected due to their dose-dependent poor water solubility and therefore limited bioavailability, and so these medicines fall into BCS class II and IV. SLS-3DP is quickly growing rapidly as a feasible method for producing medicinal tablets. The dynamic use of this technique in the pharmaceutical sectors has been demonstrated[4]. SLS-3DP was able to show its ability to create patient-tailored medications by experimenting with various printing settings. Previous research has shown the ability to control drug release from a tablet matrix by designing different lattice geometries using a precise laser. An SLS-3DP amorphous solid dispersion may be printed by changing the laser speed, chamber temperature, and surface temperature. The capability to convert poorly water-soluble medicines to their amorphous state for better solubility and bioavailability is described as novel SLS-3DP application.

Implant Drug delivery via fused Deposition Modelling 3D Printing

In the clinical treatment of bone defects, a suitable drug-loaded implant delivery system that can efficiently release antibacterial medication in the postoperative lesion region and assist heal bone infection is extremely important. The goal of the study was to see whether three-dimensional (3D) printing technology might be used to produce drug-loaded implants for bone healing. Ciprofloxacin (CIP) was selected as the model medication, and semi-solid extrusion (SSE) and fuse deposition modeling® (FDM) technologies were used [5]. The implants all had a smooth surface, excellent mechanical characteristics, adequate structural integrity, and correct dimensional size. In vitro drug release tests revealed that 3D printed implants delayed the first drug burst effect and exhibited a long-term sustained release behavior when compared to implants produced the conventional way. In the clinical treatment of bone defects, a suitable drug-loaded implant delivery system that can efficiently release antibacterial medication in the postoperative lesion region and assist heal bone infection is extremely important. The goal of the study was to see whether three-dimensional (3D) printing technology might be used to produce drug-loaded implants for bone healing. Ciprofloxacin (CIP) was selected as the model medication, and semi-solid extrusion (SSE) and fuse deposition modeling® (FDM) technologies were used. The implants all had a smooth surface, excellent mechanical characteristics, adequate structural integrity, and correct dimensional size. In vitro drug release tests revealed that 3D printed implants delayed the first drug burst effect and exhibited a long-term sustained release behavior when compared to implants produced the conventional way.

Insights from a 3D Printing Pioneer

Since 2004, Aprecia has been pioneering the technology of 3-Dimensional Printing (3DP) for pharmaceutical formulation and manufacturing. Aprecia manufacturers SPRITAM® (levetiracetam) which is the world’s first and only FDA-approved and marketed 3D-printed medication. The company continues to advance its capabilities to deliver novel drug dosage and delivery platforms to address significant unmet patient needs. Continue reading

4D Printing of Pharmaceuticals

The new idea of four-dimensional (4D) printing developed as a result of the disruptive stream of creative possibilities. The 4D printing technique, which is based on the conceptual foundations of 3D printing, incorporates a fourth dimension, namely time. The printed goods may alter their configuration (for example, change in form, property, or functionality). In addition to being made of smart materials, the programming of 4D printed things is reliant on the object’s 3D design. To be more precise, in order to induce specified morphological alterations, the structure and orientation of the smart materials inside the item must be carefully examined [6]. In layman’s words, 4D printing is usually based on the 3D printing of smart materials to build dynamic structures that may self-fold or unfold. It’s worth noting that several of these smart materials are now used in pharmaceutics and medication delivery.

This will open the door for the development of therapies that combine the personalization capabilities of 3DP with the intelligent kinetics of smart materials.

Conclusion

Though 3D printing has the potential to play a role in the individualization of medication treatment in clinical settings, considerable study is also needed to overcome the limits of the present technology .The use of ‘smart medicines’ may offer more focused treatment that is customized for the needs of each individual patient, ushering in a digital revolution in medication delivery and healthcare. Whether this will be accepted as a process will need to be seen, but there has been a steady increase in expert and research-based use of 3D printing and medication delivery systems in the last year. The worldwide 3D printing healthcare market is expected to reach US$3692 million by 2026, expanding at an 18.2 percent compound annual growth rate (CAGR) from 2019 to 2026. Currently, technological and quality control restrictions are the most significant barriers to 3D printing adoption. It is expected that once an optimal printing platform is developed, 3D printers would take over pharmaceutical shelves, ushering in a new age of digital health.

Author: Prachi Khamkar | Source: Recent Developments in Pharmaceutical 3D Printing, AM Chronicle, Aditya Chandavarkar

Reference:

- [1] Seoane-Viaño, I., Trenfield, S., Basit, A., & Goyanes, A. (2021). Translating 3D printed pharmaceuticals: From hype to real-world clinical applications. Advanced Drug Delivery Reviews, 174, 553-575. doi: 10.1016/j.addr.2021.05.003

- [2] . Kotta, S., Nair, A., & Alsabeelah, N. (2019). 3D Printing Technology in Drug Delivery: Recent Progress and Application. Current Pharmaceutical Design, 24(42), 5039-5048. doi: 10.2174/1381612825666181206123828

- [3] Elbadawi, M., McCoubrey, L., Gavins, F., Ong, J., Goyanes, A., Gaisford, S., & Basit, A. (2021). Disrupting 3D printing of medicines with machine learning. Trends In Pharmacological Sciences. doi: 10.1016/j.tips.2021.06.002

- [4] Davis, D., Thakkar, R., Su, Y., Williams, R., & Maniruzzaman, M. (2021). Selective Laser Sintering 3-Dimensional Printing as a Single Step Process to Prepare Amorphous Solid Dispersion Dosage Forms for Improved Solubility and Dissolution Rate. Journal Of Pharmaceutical Sciences, 110(4), 1432-1443. doi: 10.1016/j.xphs.2020.11.012

- [5] Cui, M., Pan, H., Li, L., Fang, D., Sun, H., & Qiao, S. et al. (2021). Exploration and preparation of patient-specific ciprofloxacin implants drug delivery system via 3D printing technologies. Journal Of Pharmaceutical Sciences. doi: 10.1016/j.xphs.2021.08.004

- [6] Firth, J., Gaisford, S., & Basit, A. (2018). A New Dimension: 4D Printing Opportunities in Pharmaceutics. 3D Printing Of Pharmaceuticals, 153-162. doi: 10.1007/978-3-319-90755-0_8

About the author

![Prachi Khamkar headshot]() Prachi Khamkar, Scientific Content writer at AM Chronicle

Prachi Khamkar, Scientific Content writer at AM Chronicle

Project Mentor, Pharmaceutical Manufacturing Operations at CiREE EduTech, Pune

Area of Interest includes 3D Printing Technology and Topical drug delivery. Received numerous awards for Scientific and Professional bodies at National and International Platforms for 3D Printng in Healthcare sector. She has published several review articles and book chapters based on 3D Printing Technology in Pharmaceutical for International Publication.