Solving Compactability Issues for the Preparation of ODTs

Introduction

Formulators often face compactability issues for the preparation of orally disintegrating tablets (ODTs) where active pharmaceutical ingredients (APIs) are poorly compressible or formed in a coated pellet. HiSORAD™, one of the best-in-class co-processed excipient for ODT, may work as the problem solver since it provides rapid disintegration with excellent compactability to ODTs. Here we present data of HiSORAD™ for such applications.

Placebo Tablet with HiSORAD™

To prepare ODTs with HiSORAD™, one or multiple APIs, flavors, sweeteners, and lubricants are blended and then compressed using a conventional tableting machine. The disintegration time of placebo tablet of 200 mg with φ8 mm is plotted against tablet hardness in Figure 1(a). Even when the tablet hardness is around 100 N, tablet with HiSORAD™ maintain the short disintegration time (<20 s). Additionally, HiSORAD™ shows excellent compactability. The tablet hardness became around 100 N under a compression force of only 5 kN (Fiqure 1(b)). Therefore, HiSORAD™ may be able to be applied to poorly compressible APIs.

Poorly Compressible API with HiSORAD

Paracetamol (PAR) is one of the poorly compressible APIs. The performance of the ODT with PAR and HiSORAD is shown in Table 1. Even with high content of PAR at 50% in ODT, HiSORAD™ could maintain the high tablet hardness with the rapid disintegration.

Table 1: Performance of ODT with (APAP)

| Content of PAR [%] | 30% | 50% |

| Compression force [kN] | 8 | 10 |

| Tablet hardness [N] | 86 | 74 |

| Disintegration time [s] | 23 | 22 |

| Component: PAR + HiSORAD™ + SSF (1.0-1.5%) + silica, colloidal hydrated (1.0%) Tableting condition: Rotary press, 200 mg, j 8 mm, flat beveled-edge shape |

||

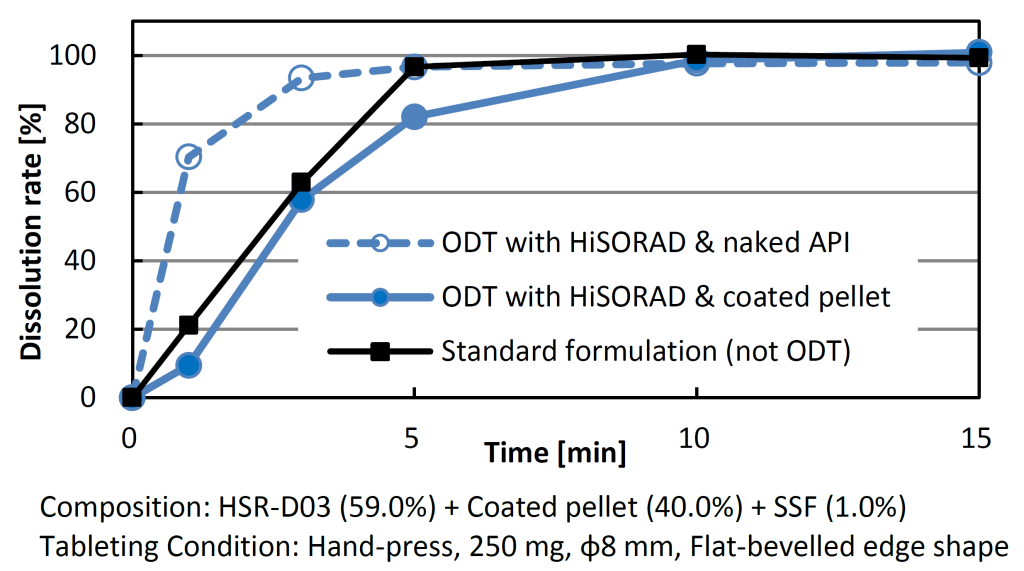

Coated pellet with HiSORAD

APIs are often included or coated to keep stability, increase bioavailability and mask their bitter taste. One of the popular techniques is coating, however, they are less compactability because they are less deformable. We evaluated the ODT performance with a coated pellet and HiSORAD™. The coated pellet was prepared with mainly PAR and EUDRAGIT RL30D. The content of the coated pellet in the ODT was 40%. The orally disintegration time of the ODT was 29 s (measured by Tricorptester of Okadaseiko) under the tablet hardness of 64 N. The dissolution profile of the ODT is shown in Figure 2. The dissolution rate at 1 min. was less than 10%, which was lower than the rate of ODT with HiSORAD and naked PAR, or the standard formulation. Therefore, the taste masking seemed to be successful in the ODT with HiSORAD and coated pellet.

Download the full article as a PDF here

Download the full article as a PDF here

Source: DAICEL