Tableting of mini-tablets in comparison with conventionally sized tablets: A comparison of tableting properties and tablet dimensions

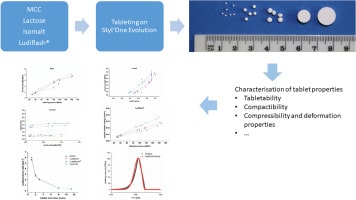

Mini-tablets are solid dosage forms with increasing interest for pharmaceutical industry due to clinical and biopharmaceutical benefits. But technological aspects on mini-tableting are not fully investigated. Therefore, the impact of punch size and tableting pressure for industrially relevant excipients like microcrystalline cellulose, lactose, isomalt and Ludiflash® are investigated using 8 and 11.28 mm punches for conventionally sized tablets and 1,2 and 3 mm punches for mini-tablets.

Highlights

Mini-tablets show higher compactibility compared to conventionally sized tablets

Mini-tablets show specific plastic energy profiles similar to conventional tablets

There is no trend for better tabletability for mini-tablets or conventionally sized tablets

Compressibility seems to be higher for conventionally sized tablets

For evaluation of the effect of tablet size on deformation behaviour and mechanical properties, compressibility, compactibility and tabletability plots are created and evaluated. Deformation behaviour is analysed by In-Die Heckel plot and modified Weibull function. Further, specific plastic energy (SPE) profiles are generated out of force-displacement plots. The effect of the adjustment of the aspect ratio towards 1 as in conventionally sized tablets on deformation behaviour and tabletability is analysed. The effect of tablet size on deformation behaviour mainly showed lower yield pressures for conventionally sized tablets, whereas comparable SPEs were obtained with all tablet sizes. Furthermore, mini-tablets indicate better compactibility, as (depending on the excipient) higher tensile strengths were obtained at lower solid fractions. However, no superior tabletability properties are obtained for mini-tablets compared to conventionally sized tablets. Continue reading on tableting of mini-tablets

Keywords

Mini-tablets, Tablets, Tablet properties, Functionalized excipients, Direct compression, Compaction simulator

Materials

Four different excipients were investigated. Microcrystalline cellulose (Vivapur 102, JRS Pharma, Germany), lactose (Tablettose® 80, Meggle, Germany), isomalt (galenIQ™721, BENEO-Palatinit, Germany) and Ludiflash®, a co-processed excipient based on d-Mannitol, crospovidone and a polymer dispersion of polyvinyl acetate (BASF, Germany). External lubrication was applied using magnesium stearate (Parteck® LUB MST, Merck, Germany) or sodium stearyl fumarate (PRUV®, JRS Pharma, Germany).