Assess the impact of your granulation process parameters with the STYL’ONE EVO

Powder granulation is commonly used in the pharmaceutical industry to improve flowability and compactibility of powders. In this case our customer wanted to develop a new direct compression grade of excipient produced by granulation.

This paper presents the methodology of MEDELPHARM Science Lab to study the effects of granulation critical process parameters on product quality attributes.

Material

Two grades of raw material (X and Y) were studied.

The granulation was performed with three different binder’s concentration (a, b and c). Granulated products were characterized in term of particle size distribution, flowability and compressibility.

Flowability was determined by bulk and tapped density (GranuPack, Granutools) and angle of repose (GranuHeap, Granutools) measurements. Compressibility was studied by performing a compression profile (STYL’One Evo, MEDELPHARM) and analysing tablets obtained (ST50, Sotax).

Results

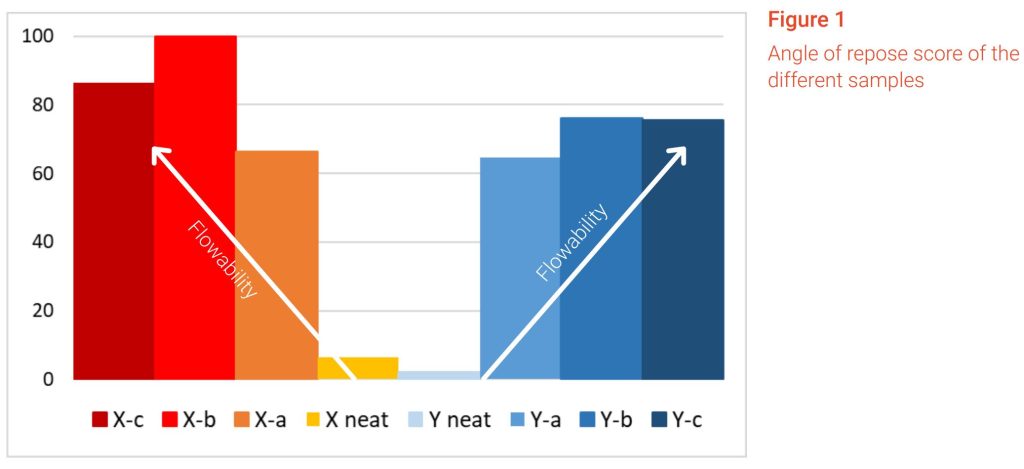

Flowability according to the angle of repose score

The angle of repose score are represented in Figure 1. The higher the angle of repose score, the better the flowability. As expected granulation improves the flowability. Flowability is enhanced by increasing binder concentration. At equivalent binder concentration, samples X and Y have similar flowability.

The angle of repose score are represented in Figure 1. The higher the angle of repose score, the better the flowability. As expected granulation improves the flowability. Flowability is enhanced by increasing binder concentration. At equivalent binder concentration, samples X and Y have similar flowability.

See the full brochure “Assess the impact of your granulation process parameters with the STYL’ONE EVO” here:

(click the picture to download the brochure)

Do you need some details or more information? Just fill in the contact form:

Source: MEDELPHARM brochure “Assess the impact of your granulation process parameters with the STYL’ONE EVO”

STYL’One Evo key benefits:

- Versatile

- Standard tooling

- Ideal for small amount of material

- Quick product and tooling changeover

- Easy to clean – easy to handle

- Simulation of any rotary tablet press

- User-friendly HMI for fast experiment setup and results with automatic studies