Influence of mesoporous silica on powder flow and electrostatic properties on short and long term

Flow aid additives are commonly used in industries to improve the processing of cohesive powders.

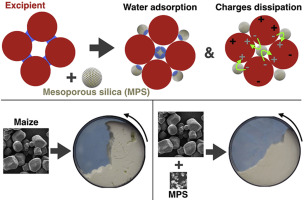

A wide variety of additives are available: magnesium or calcium stearate, fumed and mesoporous silica, talc, etc. The efficiency of the additive depends on the cohesive forces playing a role in the considered powder. For example, the physical mechanism to reduce cohesiveness induced by capillary bridges is not the same as the one to reduce electrostatic or van der Waals interactions. Moreover, the optimal quantity of flow aid agent has to be determined. The publication in the Journal of Drug Delivery Science and Technology shows how a small fraction of Mesoporous Silica Particles decreases both capillary and electrostatic cohesive forces inside powders. Three classical excipients have been selected and have been mixed with Syloid(R) Mesoporous Silica. The cohesiveness and the electrostatic properties have been characterized with GranuDum and GranuCharge instrument from GranuTools. More on electrostatic loading of powders and how to reduce them