PVA as binder in continuous twin-screw granulation

Introduction

Granulation of powder blends is a commonly applied technique for pharmaceutical formulations which have no suitable flowability or compactability or are inhomogeneous with regards to the API content. Mainly wet granulation is applied3 and here, especially continuous twin-screw granulation (TSG) is a technique that offers several benefits. TSG is more efficient, requires less water compared to batchwise techniques such as high shear granulation4,5 and granules have more favorable properties (more porous, less spherical).

Objectives

Generally, a binder is added to the powder blend to improve the characteristics of the granules. Most preferably, the binder – often HPMC, HPC or PVP based – is included in the dry blend and granules are formed by the addition of pure water. Low viscous grades of PVA (polyvinyl alcohol) are already used, however, not systematically evaluated. Therefore, this work assesses the applicability and suitability of different grades of PVA as binder in twin-screw granulation. Different formulation compositions are tested representing hydrophilic and hydrophobic nature.

Methods

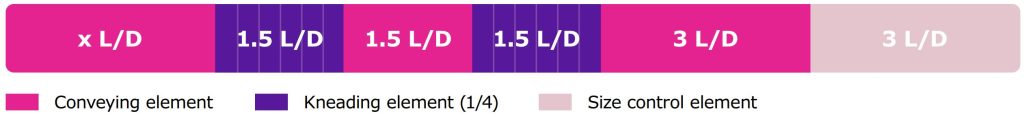

Dicalcium phosphate (DCP, Calipharm A, Innophos, USA) was used as hydrophobic excipient, Mannitol (Pearlitol 50C, Roquette, Lestrem) as hydrophilic filler. Different grades of PVA (4-88, 18-88, 40-88, MilliporeSigma, Germany) were used as binder, 5% w/w was added to the filler. Additionally, formulations with 50% w/w paracetamol semi-fine (Mallinckrodt, USA) as model compound were assessed. Twin screw granulator of ConsGmaTM-25 system (GEA, Belgium) was used at powder throughput of 20 kg/h and barrel temperature of 30°. Screw speed was set at 300, 500 and 700 rpm for hydrophobic, hydrophilic, and model compound formulation, respectively. Granules were characterized with respect to size (QicPic, Sympatec, Germany), friability (PTF 300, Pharma Test, Germany) and compactability (STYL’One, Kilian, France). Before compaction, granules were milled (ConsiGmaTM-25 system, GEA, Belgium) with grater screen of 1,500 μm on 900 rpm, 2% Magnesium stearate is added, and 400 mg tablets are produced (different forces).

Results

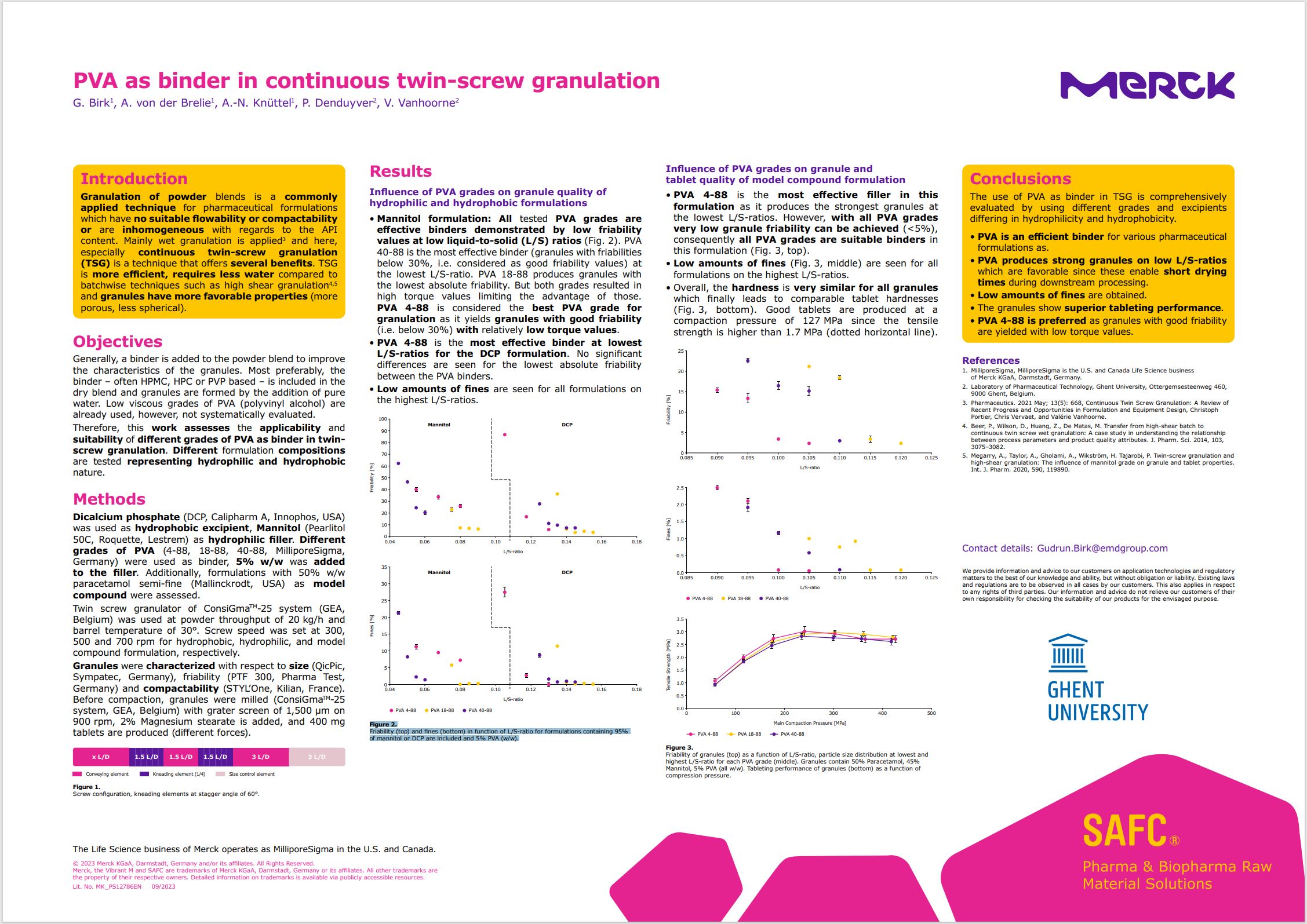

Influence of PVA grades on granule quality of hydrophilic and hydrophobic formulations

- Mannitol formulation: All tested PVA grades are effective binders demonstrated by low friability values at low liquid-to-solid (L/S) ratios (Fig. 2). PVA 40-88 is the most effective binder (granules with friabilities below 30%, i.e. considered as good friability values) at the lowest L/S-ratio. PVA 18-88 produces granules with the lowest absolute friability. But both grades resulted in high torque values limiting the advantage of those. PVA 4-88 is considered the best PVA grade for granulation as it yields granules with good friability (i.e. below 30%) with relatively low torque values.

- PVA 4-88 is the most effective binder at lowest L/S-ratios for the DCP formulation. No significant differences are seen for the lowest absolute friability between the PVA binders.

- Low amounts of fines are seen for all formulations on the highest L/S-ratios.

of mannitol or DCP are included and 5% PVA (w/w).

See the full brochure on “PVA as binder in continuous twin-screw granulation” here

(click the picture to download the brochure)

Source: Merck brochure “PVA as binder in continuous twin-screw granulation”

Do you need more information or a sample of excipients by Merck?