Optimization of Coating Processes of Mini Tablets with Polyvinylpyrrolidone Solutions in an Acoustic Levitator

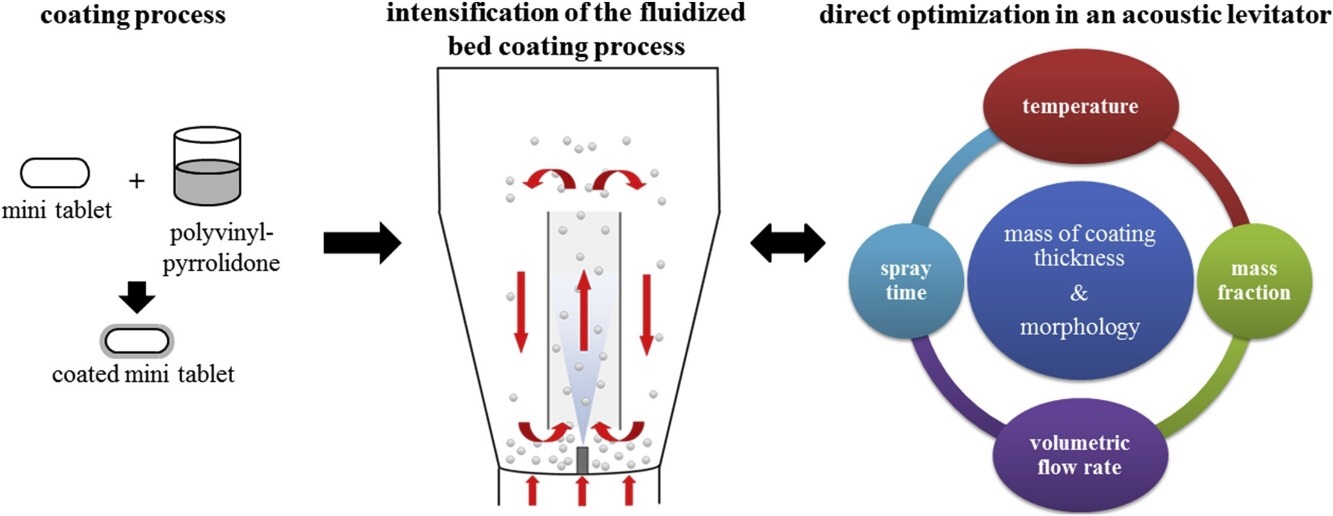

The aim of the current study is to optimize the bed fluidized coating process of mini tablets by means of an acoustic levitator. The optimized coating parameters, which have to be set in a fluidized bed reactor, can be determined by means of contactless levitation of a single mini tablet in an acoustic levitator equipped with an ultrasonic atomizer. Mini tablets were positioned in a contactless way in the levitator and coated with polyvinylpyrrolidone (PVP) solution.

The influences of process parameters on the coating, such as temperature, mass fraction, volumetric flow rate and spray time, are analyzed in an acoustic levitator in a cost- and time-saving manner. The results from the acoustic levitator were comparable to those performed in a fluidized bed reactor.

A design of experiments was performed to analyze the effects of those parameters on the mass of coating thickness. The surfaces of the samples coated in the acoustic levitator at 40 °C were comparable to samples coated in a fluidized bed reactor at 40 °C by using scanning electron microscopy (SEM). More on coating of minitablets