Isomalt as carrier for liquid APIs in tableting

INTRODUCTION

Many liquid active pharmaceutical ingredients (API) are formulated into solid oral drug delivery systems due to the safe way and simplicity of administration. First and foremost from a formulator´s point of view, excipient carriers which are suitable to convert liquids into a solid powder, have to display adequate adsorption capacity whilst maintaining flow properties that lead to fulfilling the pharmacopoeial requirements for mass uniformity.

Based on their large specific surface area, combined with their porous structure, dibasic calcium phosphates, magnesium aluminometasilicates and silicon dioxides are frequently used to convert liquid APIs into freely flowing powders. However the palatability of these materials is limited. Therefore when it comes to the formulation of chewable tablets, whereby taste and texture are decisive, then Isomalt, a disaccharide alcohol, is a preferred choice. This is due to its outstanding compactability in the manufacture of tablets. Furthermore its sugar-like taste profile and pleasant mouthfeel makes Isomalt a preferred choice wherever palatability is of importance.

In this study a direct compression type of Isomalt was evaluated to determine its suitability as solid absorbent for liquid APIs. Chewable tablets were manufactured using a high shear granulation process and a full-scale rotary tablet press.

METHODS

Characterization of adsorbent carrier Isomalt:

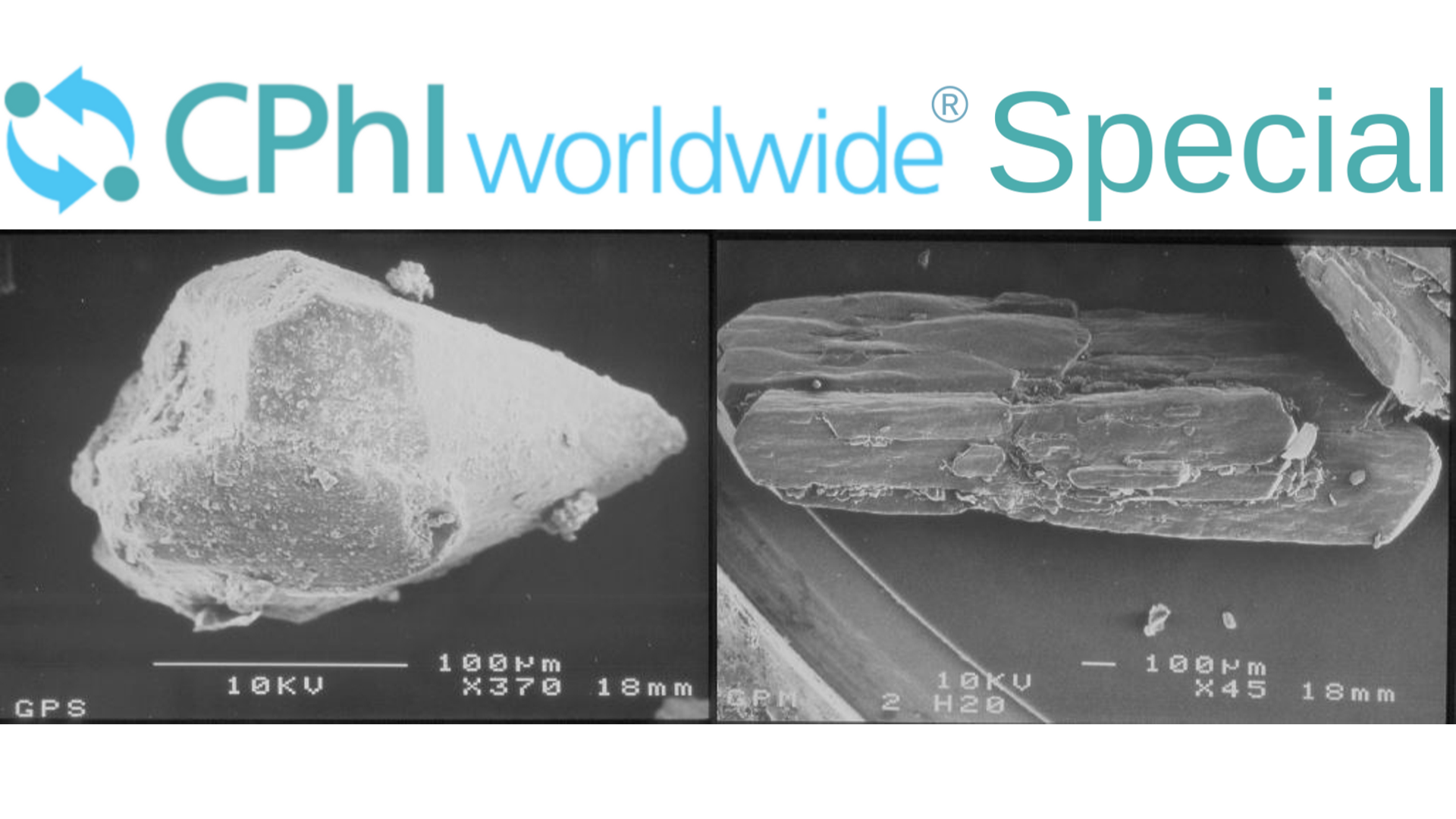

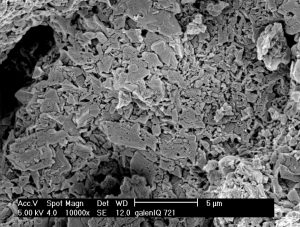

The surface characteristics were determined by SEManalysis (Hitachi, type S-510).

Blending process

A mixer granulator (Diosna, Model P1–6) was used to blend 7% (w/w) of each liquid substance homogeneously with the Isomalt. Therefore 2.5 kg of Isomalt were placed into the high shear mixer granulator. Afterwards the whole quantity of liquid was added in one step to the powder bed. Impeller speed was 250 rpm. Blending time was 180 s.

Tableting

Tablets were produced immediately after the blending step on a full scale and fully instrumented tableting press (FETTE, type P1200iG, 24 stations) using a 12 mm concave punch. Press speed was adjusted to produce 30000 tablets/h. No pre-compression step was used. Tablet hardness was adjusted in two steps between 60 N and 110 N. Tablet target weight was 600 mg.

Full Study as PDF: Isomalt carrier liquid API

Tablet mass uniformity and tablet friability

Mass uniformity was characterized according to Ph.Eur. 2.9.5. Friability was analysed according to Ph.Eur. 2.9.7.

Surface characteristics

The SEM image of the direct compression grade Isomalt reveals a sponge like structure with a multitude of cavities. Moreover as the crystals of GPS and GPM do not interlock seamlessly additional void space is created. Liquid APIs can be absorbed onto the surface and into the cavities and the void space.

Full Study as PDF: Isomalt carrier liquid API

CONCLUSION

Isomalt is found to be a convenient carrier for liquid APIs in the manufacture of DC chewable tablets. 7% (w/w) of linseed oil and two simethicone fluids with different viscosities were each loaded onto a direct compression type Isomalt in a simple blending process. Loaded Isomalt showed suitable flow properties for tableting in an industrial scale rotary tablet press equipped with a force feeder. Tablet hardness yield was excellent. Both tablet mass uniformity and friability complied with pharmacopoeial standards.

Interested in more details on the possibilities of isomalt galenIQ™721? See here.

Are you interested to receive more information or a sample? Just contact us