New Characterization Measures of Pore Shape and Connectivity Applied to Coatings used for Controlled Drug Release

Pore geometry characterization-methods are important tools for understanding how pore structure influences properties such as transport through a porous material. Bottlenecks can have a large influence on transport and related properties. However, existing methods only catch certain types of bottleneck effects caused by variations in pore size.

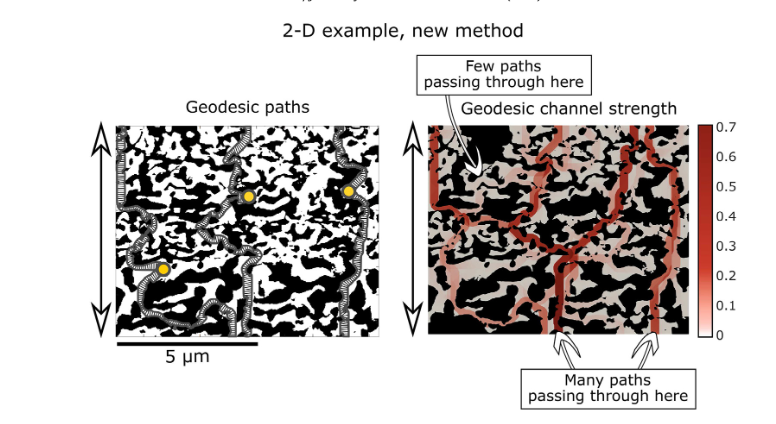

We here introduce a new measure, geodesic channel strength, which captures a different type of bottleneck effect caused by many paths coinciding in the same pore. We further develop new variants of pore size measures and propose a new way of visualizing 3-D characterization results using layered images. The new measures together with existing measures were used to characterize and visualize properties of 3-D FIB-SEM images of three leached ethyl-cellulose/hydroxypropyl-cellulose films.

All films were shown to be anisotropic, and the strongest anisotropy was found in the film with lowest porosity. This film had very tortuous paths and strong geodesic channel-bottlenecks, while the paths through the other two films were relatively straight with well-connected pore networks. The geodesic channel strength was shown to give important new visual and quantitative insights about connectivity, and the new pore size measures provided useful information about anisotropies and inhomogeneities in the pore structures. The methods have been implemented in the freely available software MIST.

Download the full article as pdf: New Characterization Measures of Pore Shape and Connectivity Applied to Coatings used for Controlled Drug Release

or read it here

Materials:

Ethyl Cellulose/Hydroxypropyl Cellulose Polymer Films

The polymer films were produced from the water soluble polymer, HPC, and the water insoluble polymer, EC. The two polymers were dissolved in ethanol and sprayed onto a rotating drum to create a film. The spraying direction was the direction of transport through the film, corresponding to the direction of transport through the coatings of pharmaceutical pellets. After drying, the films were cut off from the drum and the HPC were leached out to create 0.5 cm × 0.5 cm square porous films. The weight percentages of the water soluble polymer HPC were 22, 30, and 45. The films were denoted HPC22, HPC30 and HPC45, respectively. For a detailed description of the production process see Fager et al.

Sandra Barman, Cecilia Fager, Magnus Röding, Niklas Lorén, Christian von Corswant, Eva Olsson, David Bolin, Holger Rootzén,

New Characterization Measures of Pore Shape and Connectivity Applied to Coatings used for Controlled Drug Release, Journal of Pharmaceutical Sciences,

Volume 110, Issue 7, 2021, Pages 2753-2764,

https://doi.org/10.1016/j.xphs.2021.02.024.