Advanced Tablet Coating Development: Applying Optical Coherence Tomography (OCT) as a PAT Tool for PVA Based Coatings

Purpose: Novel tablet coating approaches include the development of continuous coating technologies. This requires a high level of automation to assure the quality and safety of the final coated product. Despite automation of control procedures also approaches of in-line process analytical technology (PAT) become more relevant.

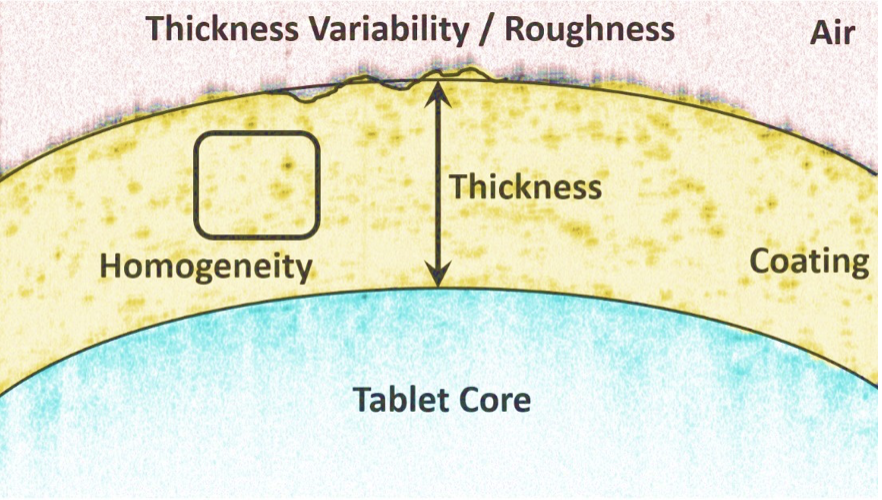

Optical coherence tomography (OCT) is a highly promising technology that allows rapid (even in-line/real-time) monitoring of coating quality without the requirement of significant calibration steps. It provides direct information about multiple critical quality attributes of coated dosage forms. The potential of this technology has been evaluated during formulation development on PVA based formulations.

Methods: Tablet coating was performed using a drum coater type LDCS from Freund-Vector. An industrial OCT system (OseeT Pharma 1D) from Phyllon (Graz, Austria) was applied for coating layer analysis. At-line OCT data was generated in a miniaturized drum setup tailored to mimic a large-scale pan coating process.

Additional 3D surface images of the coating were generated by combining multiple 1D scans to cross-sectional images (B-scans). Multiple B-scans were combined to generate a 3D image of the tablet surface. The impact of different plasticizers on the surface finishing of a PVA based coating was assessed. Glycerol, spray dried mannitol, spray dried sorbitol, triacetin, and triethyl citrate were used as plasticizers. SEM images of the coating surfaces as well as the side cut of representative samples were evaluated concerning coating film thickness and homogeneity and compared to OCT data.

Results: The OCT system could be successfully used to characterize film coatings and to determine the thickness of the coating layer as well as the surface roughness for selected sample formulations. The 1D scans revealed that triethyl citrate (Ra: 2.59 µm), triacetin (Ra: 2.59 µm), mannitol (Ra: 2.96 µm) as well as sorbitol (Ra: 2.98 µm) at concentrations of approximately 30% in the final coating suspension showed a very good effect on the surface roughness and final finishing of the coated tablets. On the other hand, for the same concentrations of glycerol the plasticizing effect was less pronounced, with a roughness of 3.23 µm. A similar tendency was obtained using 3D OCT scans. SEM images confirmed the results and could also be linked to the identified coating thickness in the OCT scans.

Conclusion: It could be shown that a better understanding of coating quality attributes brings significant benefit already in early formulation and process development. Effects of different excipients on the coating quality can be assessed rapidly which can speed up the formulation development. The system can also easily be integrated in the pan coating process and can be used for in-line monitoring of film properties.

Read more: Link to 2019 AAPS PharmSci 360

Thomas Kipping, Advanced Tablet Coating Development: Applying Optical Coherence Tomography (OCT) as a PAT Tool for PVA Based Coatings, https://www.merckmillipore.com/DE/en/20191001_161955?ReferrerURL=https%3A%2F%2Fwww.google.com%2F

More information: New developments around OCT and OSeeT