Maltodextrin-Based Cross-Linked Electrospun Mats as Sustainable Sorbents for the Removal of Atenolol from Water

Abstract

Introduction

The use of polysaccharides as sustainable alternatives to fossil-based plastics has gained increasing scientific and industrial interest, aiming to move toward a circular economy [1,2]. In this context, starch and cellulose have been applied in the packaging industry and for bio-composite production [3,4,5,6,7]. They have also been exploited in various fields such as food, pharmaceuticals, environmental science, and medical science [8,9,10,11,12,13,14,15,16]. Produced by enzymatic conversion from starch, maltodextrins are D-glucose-based water-soluble polymers, used mainly as pharmaceutical and food additives [17]. The dextrose equivalent (DE) is a measure of the degree of polymerisation of each maltodextrin, which is determined by its reducing equivalent against the same glucose mass. The DE for maltodextrins is usually lower than 20 [18]. Maltodextrins have been utilised as affordable bioderived building blocks to create cross-linked polymers [19,20,21,22,23,24,25,26]. Furthermore, maltodextrins have been successfully processed via electrospinning to obtain polysaccharide-based fibres [27].

Electrospinning is a cost-effective, facile, and flexible processing technique that allows the production of fibres from electrically charged jets of polymer solutions [28]. The strength of this technique is associated with the high surface-to-volume ratio of the mats produced, which are characterised by fibres with diameters ranging from micrometres to nanoscale [29,30,31]. However, the use of toxic or flammable organic solvents is often needed to dissolve the polymer, which limits industrial production due to environmental and safety regulations [32,33,34,35,36,37]. For this reason, the reduction or substitution of hazardous substances is an active research field, in agreement with the Green Chemistry principles [38,39]. In this framework, the electrospinning of maltodextrins using water and ethanol/water mixtures as the solvent media was reported by Stijnman et al. [27] and Vargas-Campos et al. [40], respectively. Maillard reactions have been exploited to cross-link electrospun protein-containing maltodextrin fibres, as demonstrated by Kutzli et al. and Gibis et al. [41,42,43,44]. Similarly, Ruggeri et al. cross-linked maltodextrin amino acid electrospun scaffolds for skin tissue engineering [45]. Environmental studies related to the use of polysaccharide electrospun fibres were carried out by Huang et al. [46] and Nthunya et al. [47], who exploited chitosan-based fibres to remove metal ions and phenols, respectively. Recently, Mantripragada et al. [48] reported the use of soy protein-coated cellulose-based electrospun membranes for the remediation of emerging contaminants from water.

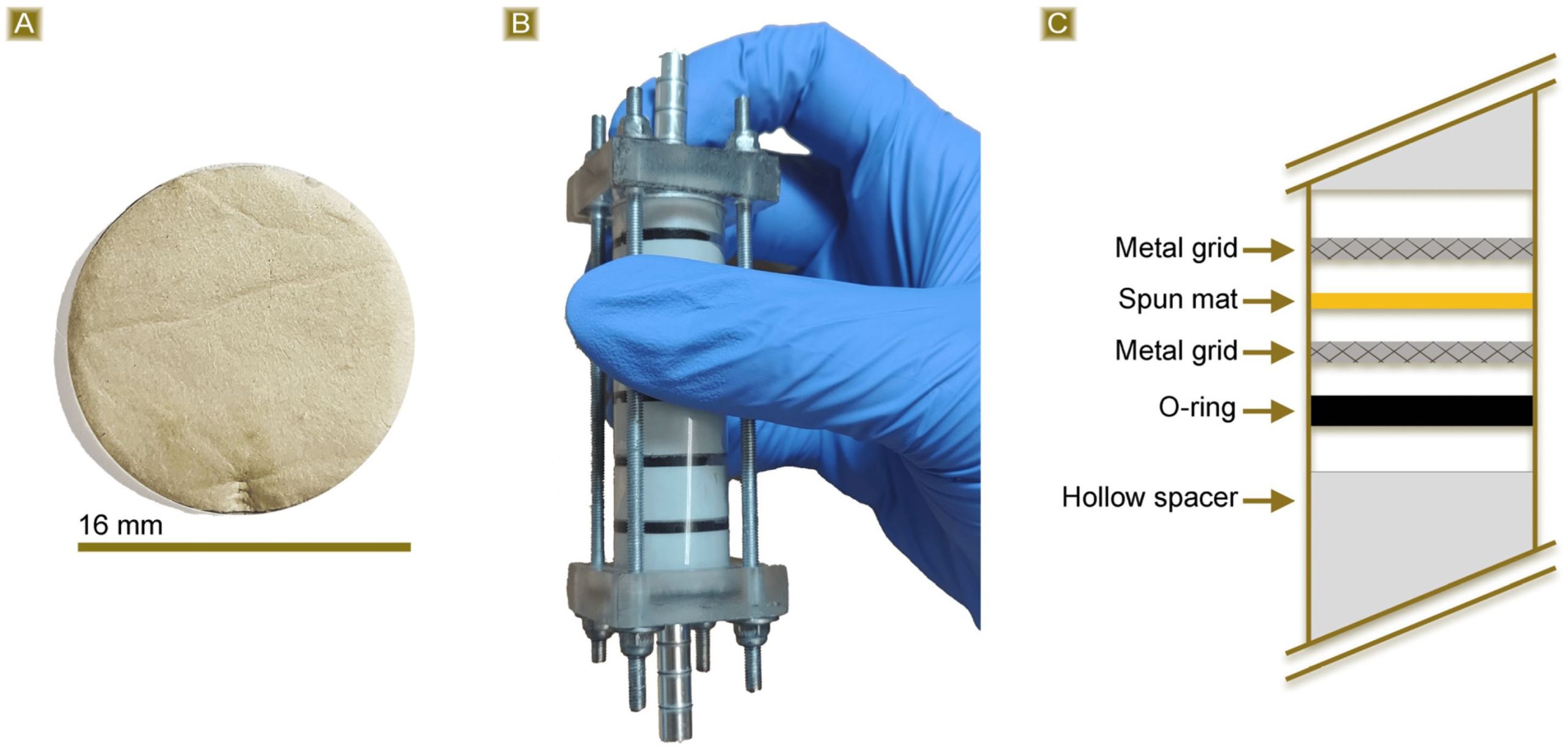

Emerging contaminants are composed of different classes of compounds, such as active personal care products, pharmaceutical ingredients, pesticides, and plasticisers. There is concern regarding their presence in the environment. This is mainly due to experimental data showing their possible aptitude to cause negative outcomes on flora, fauna, and human health. Additionally, these substances are difficult to degrade and are resistant to common water treatment processes [49,50,51,52,53]. Pharmaceuticals such as β-blockers are found in the environment at low but meaningful levels. While not highly persistent, many are considered “pseudo-persistent” due to continuous discharge into the environment from various sources [54,55]. Atenolol is one of the most widely used β-blockers, mainly in the treatment of cardiovascular conditions including abnormal heart rhythms, high blood pressure, and angina pectoris [56,57]. High prescription rates and incomplete metabolism can lead to the presence of atenolol in municipal wastewater effluents up to the µg/L scale, causing the potential for its deposition into aquatic ecosystems and exposure consequences for aquatic wildlife [58,59]. In this work, nonwoven mats were first obtained by the electrospinning technique and then cross-linked via a mild thermal treatment. Subsequently, the cured fibres were tested for their potential to remove atenolol, an emerging pollutant, from water.

Download the full article as PDF here: Maltodextrin-Based Cross-Linked Electrospun Mats as Sustainable Sorbents for the Removal of Atenolol from Water

or read it here

Materials

Maltodextrins with a DE value of 2 (Glucidex 2®, GLU2) were provided by Roquette Freres (Lestrem, France), while citric acid (99%) (CIT) and atenolol (AT) were purchased from Sigma-Aldrich (Darmstadt, Germany). GLU2 was dried in an oven at 75 °C, for 24 h, to reach the complete evaporation of the water adsorbed, i.e., constant weight of the material.

Cecone, C.; Fiume, V.; Bracco, P.; Zanetti, M. Maltodextrin-Based Cross-Linked Electrospun Mats as Sustainable Sorbents for the Removal of Atenolol from Water. Polymers 2024, 16, 752. https://doi.org/10.3390/polym16060752

Read more on Maltodextrin here:

- Significant Progress in Improving Atorvastatin Dissolution Rate

- Orodispersible Films: Current Innovations and Emerging Trends

- Low melting mixtures: Neoteric green solvents for flavor formulation