Current State of Minitablet Product Design: A Review

Abstract

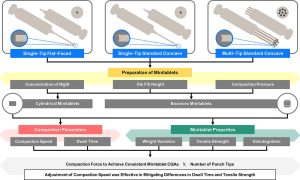

Interest in minitablets (MTs) has grown exponentially over the last 20 years and especially the last decade, as evidenced by the number of publications cited in Scopus and PubMed. MTs offer significant opportunities for personalized medicine, dose titration and flexible dosing, taste masking, and customizing drug delivery systems. Advances in specialized MT tooling, manufacturing, and characterization instrumentation have overcome many of the earlier development issues. Breakthrough MT swallowability, acceptability, and palatability research have challenged the long-standing idea that only liquids are acceptable dosage forms for infants and young children. Minitablets have been shown to be a highly acceptable dosage form for infants, small children, and geriatric patients who have difficulty swallowing. This review discusses the current state of MT applications, acceptability in pediatric and geriatric populations, medication adherence, manufacturing processes such as tableting and coating, running powder and tablet characterization, packaging and MT dispensing, and regulatory considerations.

Introduction

The design of orally administered therapeutics that meet patient needs has become more of a focus for pharmaceutical scientists over the past decade. Tablets and capsules remain the preferred oral dosage forms due to superior stability compared to liquid dosage forms, better patient compliance, and lower production costs.1,2 However, conventional monolithic dosage units pose issues related to swallowability for specific patient populations, such as children and the elderly, resulting in nonadherence to the therapy.3, 4, 5, 6 Additionally, certain disease conditions weaken the throat muscles making it difficult to swallow4,7, requiring practices such as preparing oral suspensions from tablets or splitting tablets to address swallowing difficulties. Such practices pose risks related to dose accuracy, stability, safety, and efficacy.8,9

To address the swallowability issues associated with conventional size oral solids, pharmaceutical scientists started focusing on smaller oral solid dosage forms, referred as minitablets (MTs). This review focuses on the current state of use and manufacture of MTs. Throughout this review, potential advantages of MT based dosage forms will be described. The authors acknowledge, however, that MT based dosage forms have limitations and potential liabilities. MTs are tablets of smaller diameters compared to conventional tablets. Currently, there are no regulatory guidelines that define MT size ranges. The literature commonly designates tablets of diameters ≤4 mm as MTs10,11 or microtablets (≤2 mm in particular)12. MTs’ small size is also a potential liability associated with handling. This liability can manifest itself in manufacture, packaging, dispensing and administration. It is essential that the product design scientist and process engineer, along with their cross functional partners consider the entire manufacturing and use scenarios in the decision to develop a MT based drug product for clinical and/or commercial use.

Early MT references can be traced back to a study conducted in 1984, where 4-mm MTs were designed to study the impact of guar gum on carbohydrate and lipid metabolism in Type II diabetic patients.11 MTs offer several advantages due to their small size; they provide much greater dose flexibility13, 14, 15, improve patient compliance2, may reduce the risk of dose dumping, enable the feasibility of fixed-dose combination products16, enable sprinkling on food4, and provide independence from feeding or fasting state to their transit time through the gastrointestinal tract and therefore to the therapeutic performance of the drug product 17.

MT product designs can also help in achieving complex drug release profiles which are difficult to achieve by conventional tablets. For example, manufacture and coating of 3-mm theophylline MTs helped to obtain a zero-order release profile which was not accomplished by conventional size tablets and coated pellets.10 Additionally, in the case of paracetamol MTs demonstrated improved compactability compared to conventional size tablets.18

Despite their numerous advantages, MTs had not been explored extensively until the early 2000s. Two major hurdles slowed MT research. One of these hurdles was the availability of durable specialized MT tooling and advanced manufacturing and characterization equipment at affordable prices. MT manufacturing is more challenging compared to conventional tablets and requires superior powder properties and specialized manufacturing accessories to ensure uniform die filling, tablet weight, and content. Subsequent processing, such as film coating and packaging need to be adapted or altered to account for the small tablet sizes. Additionally, conventional tablet characterization techniques such hardness testing and friability needed to be modified. MTs also present special container closure and dispensing requirements. The second hurdle was a scarcity of well controlled studies that evaluated the swallowability and acceptability of MTs in the pediatric and geriatric target populations. Until the early 2000s, liquid formulations were the gold standard for delivering drugs to infants and preschoolers. In fact, it was generally considered unethical to consider administering a solid dosage form to infants and preschoolers.

Recent advances in the manufacturing space, MT characterization tools, and the opportunity to study MT acceptability in pediatric population has led to a tremendous increase in MT research over the past two decades which is evident from the rise in MT publications shown in Figure 1. and approved minitablet products. Table 1. shows marketed oral solid drug products using MTs.

Read more here

Saikishore Meruva, Aditya B. Singaraju, Bhavani Prasad Vinjamuri, Robert Ternik, William C. Stagner, Current State of Minitablet Product Design: A Review, Journal of Pharmaceutical Sciences, 2024, ISSN 0022-3549, https://doi.org/10.1016/j.xphs.2024.02.016.

Read also this interesting article on minitablets: