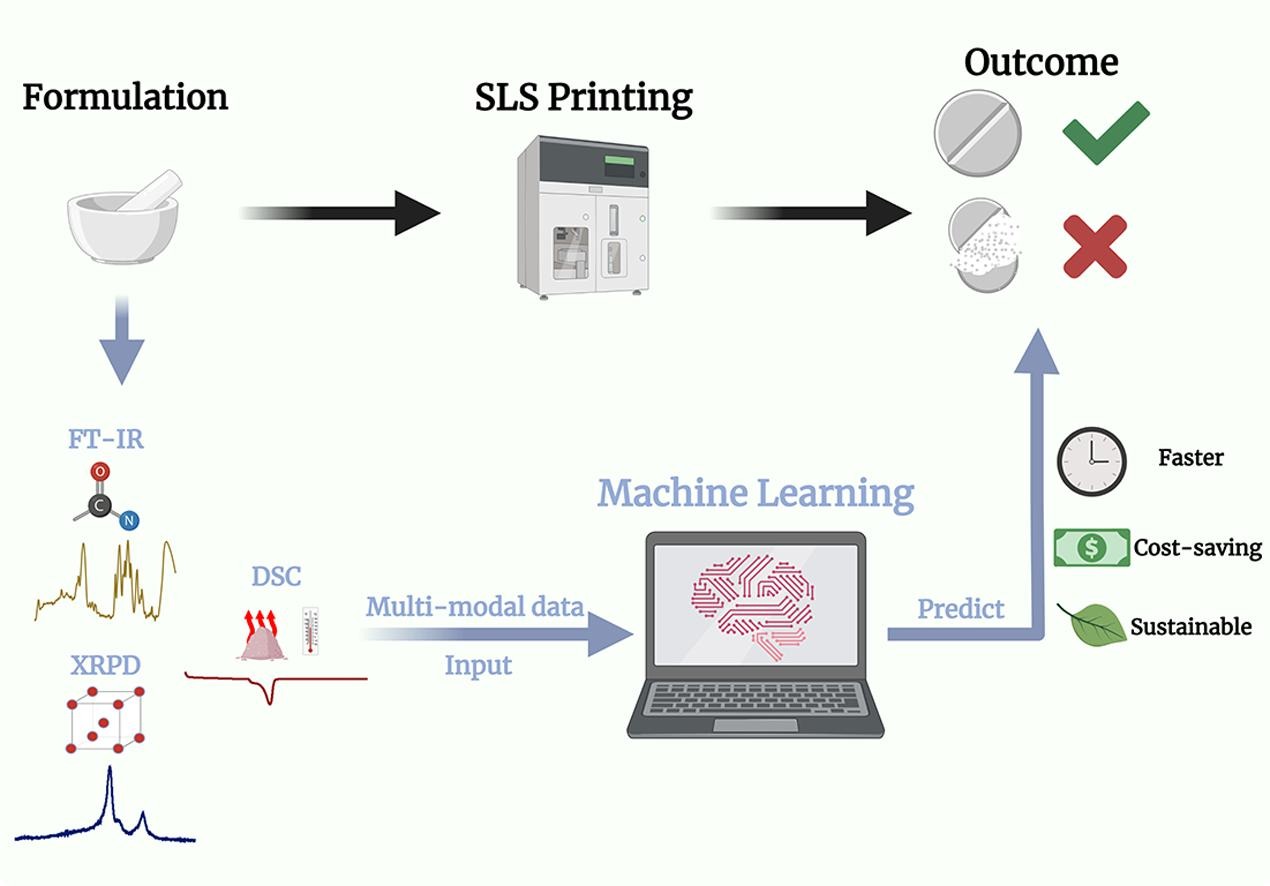

Machine learning using multi-modal data predicts the production of selective laser sintered 3D printed drug products

Three-dimensional (3D) printing is drastically redefining medicine production, offering digital precision and personalized design opportunities. One emerging 3D printing technology is selective laser sintering (SLS), which is garnering attention for its high precision, and compatibility with a wide range of pharmaceutical materials, including low-solubility compounds. However, the full potential of SLS for medicines is yet to be realized, requiring expertise and considerable time-consuming and resource-intensive trial-and-error research. Machine learning (ML), a subset of artificial intelligence, is an in silico tool that is accomplishing remarkable breakthroughs in several sectors for its ability to make highly accurate predictions.

Therefore, the present study harnessed ML to predict the printability of SLS formulations. Using a dataset of 170 formulations from 78 materials, ML models were developed from inputs that included the formulation composition and characterization data retrieved from Fourier-transformed infrared spectroscopy (FT-IR), X-ray powder diffraction (XRPD) and differential scanning calorimetry (DSC). Multiple ML models were explored, including supervised and unsupervised approaches. The results revealed that ML can achieve high accuracies, by using the formulation composition leading to a maximum F1 score of 81.9%. Using the FT-IR, XRPD and DSC data as inputs resulted in an F1 score of 84.2%, 81.3%, and 80.1%, respectively.

A subsequent ML pipeline was built to combine the predictions from FT-IR, XRPD and DSC into one consensus model, where the F1 score was found to further increase to 88.9%. Therefore, it was determined for the first time that ML predictions of 3D printability benefit from multi-modal data, combining numeric, spectral, thermogram and diffraction data. The study lays the groundwork for leveraging existing characterization data for developing high-performing computational models to accelerate formulation development.

Table S1: Materials:

| Material | Supplier |

| ALGINIC ACID FROM BROWN ALGAE | (Sigma Aldrich, UK) |

| AQOAT AS-HG SHIN ETSU | (Shin-Etsu, UK) |

| AQOAT AS-LG SHIN ETSU | (Shin-Etsu, UK) |

| AQOAT AS-MG SHIN ETSU | (Shin-Etsu, UK) |

| Aqualon EC-N50 | (Ashland, UK) |

| AQUASOLVE AS-LG | (Ashland, UK) |

| BENECEL A15LV PH PRM | (Ashland, UK) |

| Caffeine | (Sigma Aldrich, UK) |

| Candurin | (Merck, UK) |

| Candurin Red Sprakle | (Merck, UK) |

| Carbopol 971 | (Lubrizol, USA) |

| CELLULOSE ACETATE ALDRICH 39.8% ACETYL CONTENT MW 30000 | (Sigma Aldrich, UK) |

| CHITOSAN MEDIUM MW | (Sigma Aldrich, UK) |

| Citric acid monohydrate | (Sigma Aldrich, UK) |

| CMC BLANOSE 12M31P EP | (Ashland, UK) |

| CMC BLANOSE 7HF-PH | (Ashland, UK) |

| CMC BLANOSE 9M31F-PHARM | (Ashland, UK) |

| CMC BLANOSE CMC 7MF PH | (Ashland, UK) |

| D-MALTOSE | (Sigma Aldrich, UK) |

| ETHYLCELLULOSE (AQUALON EC-N7) | (Ashland, UK) |

| ETHYLCELLULOSE CP 10 | (Acros, UK) |

| ETHYLCELLULOSE 300 cp | (Sigma Aldrich, UK) |

| ETHYLCELLULOSE 46 Cp | (Sigma Aldrich, UK) |

| EUDRAGIT EPO | (Evoniks, UK) |

| EUDRAGIT L100 | (Evoniks, UK) |

| EUDRAGIT L100-55 | (Evoniks, UK) |

| EUDRAGIT RL PO | (Evoniks, UK) |

| Eudragit RL000 | (Evoniks, UK) |

| EUDRAGIT RS PO | (Evoniks, UK) |

| EUDRAGIT S100 | (Evoniks, UK) |

| Glycerol Monostearate | (Alfa Aesar, UK) |

| GUM GUAR | (Sigma Aldrich, UK) |

| HPC KLUCEL EF PHARM | (Ashland, UK) |

| HPC KLUCEL GF PHARM | (Ashland, UK) |

| HPC KLUCEL LF PHARM | (Ashland, UK) |

| HPMC BENECEL K100LV PH PRM | (Ashland, UK) |

| HPMC BENECEL K4M PHARM CR | (Ashland, UK) |

| Ibuprofen | (Sigma Aldrich, UK) |

| Klucel ELF | (Ashland, UK) |

| KOLLICOAT IR | (BASF, UK) |

| KOLLICOAT PROTECT (KOLLICOAT IR + PVA) | (BASF, UK) |

| Kollidon CL-M | (BASF, UK) |

| Kollidon SR | (BASF, UK) |

| KOLLIDON VA-64 | (BASF, UK) |

| KOLLIPHOR P188 | (BASF, UK) |

| MAGNESIUM STEARATE | (Sigma Aldrich, UK) |

| Mannitol | (Sigma Aldrich, UK) |

| METHYL PARABEN | (Sigma Aldrich, UK) |

| OPADRY AMB II: HIGH PERFORMANCE MOISTURE BARRIER FILM COATING RED | (Colorcon, UK) |

| OPADRY AMB II: HIGH PERFORMANCE MOISTURE BARRIER FILM COATING YELLOW | (Colorcon, UK) |

| Paracetamol | (Sigma Aldrich, UK) |

| PEG 2000 | (Sigma Aldrich, UK) |

| PEG 400 | (Sigma Aldrich, UK) |

| PEG 6000 | (Sigma Aldrich, UK) |

| PEO 100 Kda | (Sigma Aldrich, UK) |

| PEO 300 Kda | (Sigma Aldrich, UK) |

| PEO 1M | (Sigma Aldrich, UK) |

| PEO 7M | (Sigma Aldrich, UK) |

| PEO 8M | (Sigma Aldrich, UK) |

| PLASDONE S-630 | (Ashland, UK) |

| POLYPLASDONE XL | (Ashland, UK) |

| Povacoat F | (Daido Chemical Co, Japan) |

| POVACOAT MP | (Daido Chemical Co, Japan) |

| Polypropylene Glycol | (Sigma Aldrich, UK) |

| PVA 87-89% HYDROLISED (MW 13-23 Kda) | (Sigma Aldrich, UK) |

| PVA 87-90% HYDR. (MW 30-70 Kda) | (Sigma Aldrich, UK) |

| PVP 10000 MW | (Sigma Aldrich, UK) |

| PVP 40000 MW | (Sigma Aldrich, UK) |

| PVP 40T | (Sigma Aldrich, UK) |

| PVP360000 MW | (Sigma Aldrich, UK) |

| Riboflavin | (Sigma Aldrich, UK) |

| Sodium startch glycolate | (Sigma Aldrich, UK) |

| SOLUPLUS | (BASF, UK) |

| STEARAMIDE (N-N-ETHYLENBIS) | (Cambridge Bioscience, UK) |

| Talc | (VWR, UK) |

| Triethyl citrate | (Sigma Aldrich, UK) |

| Tween 80 | (Fisher Scientific, UK) |

| Xanthan Gum | (Sigma Aldrich, UK) |

| Xylitol | (Sigma Aldrich, UK) |

Download the full article as PDF here Machine learning using multi-modal data predicts the production of selective laser sintered 3D printed drug products

or read it here

Youssef Abdalla, Moe Elbadawi, Mengxuan Ji, Manal Alkahtani, Atheer Awad, Mine Orlu, Simon Gaisford, Abdul W. Basit, Machine learning using multi-modal data predicts the production of selective laser sintered 3D printed drug products, International Journal of Pharmaceutics, Volume 633, 2023, 122628, ISSN 0378-5173, https://doi.org/10.1016/j.ijpharm.2023.122628.