Nanoemulsion: An Emerging Novel Technology for Improving the Bioavailability of Drugs

Abstract

The pharmaceutical sector has made considerable strides recently, emphasizing improving drug delivery methods to increase the bioavailability of various drugs. When used as a medication delivery method, nanoemulsions have multiple benefits. Their small droplet size, which is generally between 20 and 200 nanometers, creates a significant interfacial area for drug dissolution, improving the solubility and bioavailability of drugs that are weakly water-soluble. Additionally, nanoemulsions are a flexible platform for drug administration across various therapeutic areas since they can encapsulate hydrophilic and hydrophobic medicines. Nanoemulsion can be formulated in multiple dosage forms, for example, gels, creams, foams, aerosols, and sprays by using low-cost standard operative processes and also be taken orally, topically, topically, intravenously, intrapulmonary, intranasally, and intraocularly. The article explores nanoemulsion formulation and production methods, emphasizing the role of surfactants and cosurfactants in creating stable formulations. In order to customize nanoemulsions to particular medication delivery requirements, the choice of components and production techniques is crucial in assuring the stability and efficacy of the finished product. Nanoemulsions are a cutting-edge technology with a lot of potential for improving medication bioavailability in a variety of therapeutic contexts. They are a useful tool in the creation of innovative pharmaceutical formulations due to their capacity to enhance drug solubility, stability, and delivery. Nanoemulsions are positioned to play a crucial role in boosting medication delivery and enhancing patient outcomes as this field of study continues to advance.

Introduction

Nanoemulsions, also known as nanometric-sized emulsions, are fine water-in-oil (w/o) and oil-in-water (o/w) dispersions of two immiscible fluids, as opposed to the milky-white hue concomitant with coarse dispersion. These 20–200 nm droplets are stabilized by adding the appropriate amphiphilic emulsifiers or emulsifiers. Consequently, nanoemulsions are also known as mini-emulsions. Due to kinetic stability, nanoemulsions (NE) are stable on heterogeneous systems, in contrast to microemulsions (ME). Although nanoemulsions are unique due to their extended physical constancy and are also known as “potential thermodynamic stability,” they do not appear to aggregate or flocculate. The history of nanoemulsions can be traced back to the early 20th century when researchers first began experimenting with colloidal systems. Initial work focused on macroemulsions and microemulsions, but it laid the groundwork for the development of nanoemulsions. Nanoemulsions as a distinct category of emulsions gained significant attention in the 1990s. Researchers started to explore their unique properties, such as their extremely small droplet sizes, typically ranging from 20 to 200 nanometers. This period marked a shift toward understanding the potential applications of nanoemulsions, particularly in the pharmaceutical and food industries [1–5].

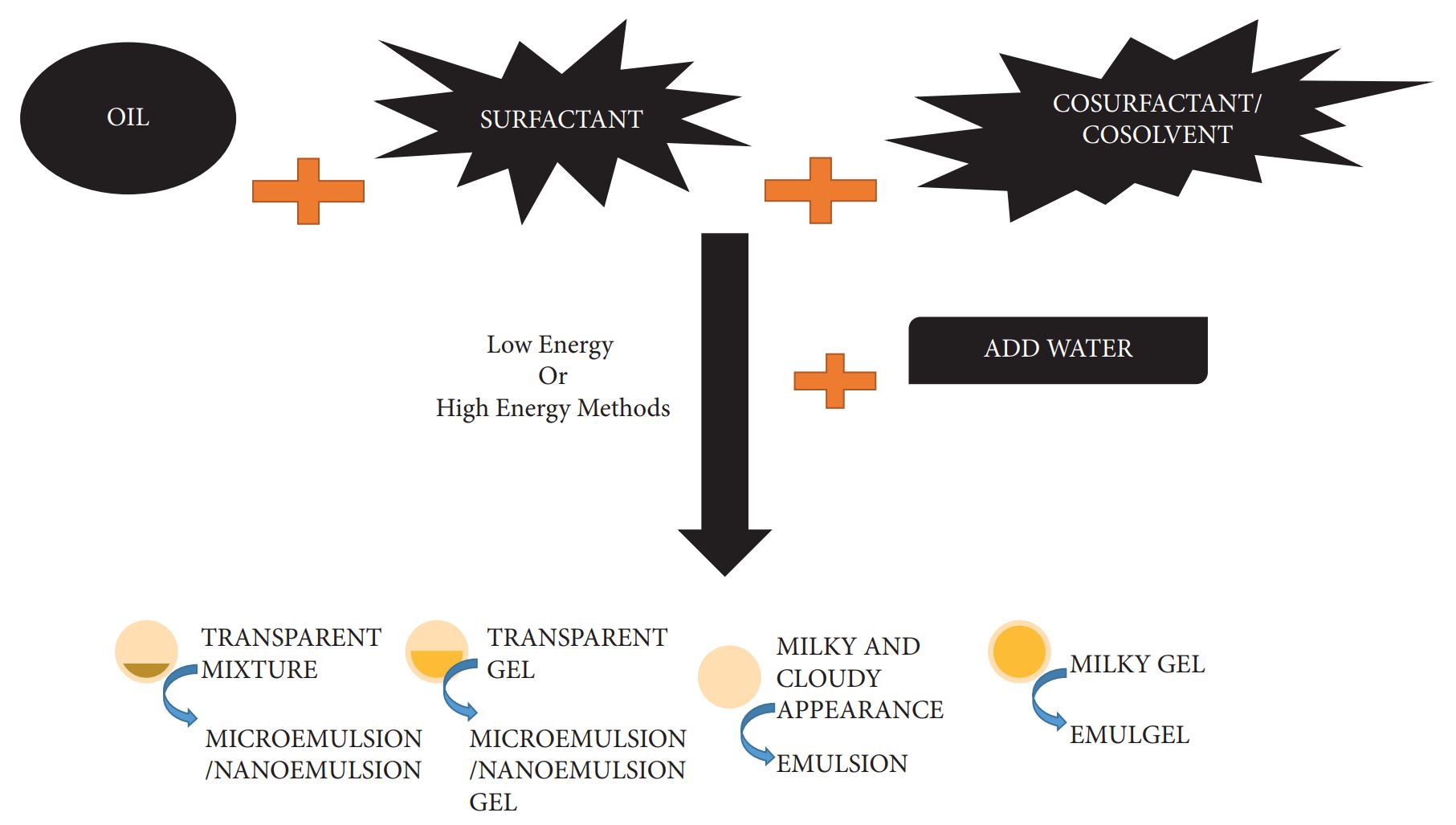

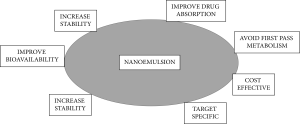

The following benefits explain why nanoemulsion is appealing in both the personal care and cosmetics industry and in healthcare (Figure 1) [6–25].

(1)Nanoemulsion can be produced with lower concentrations of emulsifier (3–10%) than ME, which needs a high concentration (20%).(2)Nanoemulsion helps in the effective transportation of active substances through a semipermeable membrane, and due to the large surface area, penetration increases in the emulsion system.(3)Besides preventing droplet flocculation, nanoemulsions’ small globule size additionally avoids larger droplet flocculation. This enables the system to survive in solitude without being divided.(4)Tiny droplets or globules in a nanoemulsion are responsible for the reduction in gravitational forces and Brownian motion. Consequently, there is no creaming or sedimentation while the product is being stored.(5)Nanoemulsions are simple to make and do not require a lot of energy to create. Nanoemulsion formulations are said to improve the reproducibility of the plasma concentration profile and bioavailability.(6)Nanoemulsions are super solvents because they include both hydrophilic and lipophilic drugs.(7)When the active ingredient is enclosed within a nanoemulsion formulation, the medicine is protected against environmental variables including pH hydrolysis and oxidation.(8)Nanoemulsions can be formed as gels, creams, foams, aerosols, and sprays, among other dosage forms. Additionally, they may be given orally, topically, intravenously, intrapulmonary, intranasally, and intramuscularly. In comparison to micelles dispersion, nanoemulsions have a higher solubilization capacity, and they are more thermo-kinetically stable.(9)It helps avoid hepatic first-pass metabolism because it is an oil/lipid-based drug delivery mechanism.(10)Nanoemulsion can also effectively mask the metallic and bitter tastes of medications that might induce unpleasant side effects such as nausea and vomiting.(11)Nanoemulsions can be useful as an alternative to liposomes and vesicles (which have poor stability), and they can occasionally be built to form lamellar liquid crystalline encircling globules.

Despite these tools, there is still a somewhat unimportant perception of the creation, production, construction, and handling of nanoemulsions. This impression is primarily attributable to the reality that traditional notions of the formation of emulsion and stability barely get extended. The proof for current perception is built up by this collective insufficiency. This study focuses on the nanoemulsion concept as a novel delivery system for poorly aqueous soluble drug candidates to enhance their bioavailability through encapsulation into oil/lipid for the management of numerous diseases, such as hypertension, diabetes, and cancer disease, and reduces the dose-related side effect of the drugs.

A wide range of advantages and standout benefits are provided by creating nanoemulsions for diverse drug delivery methods, greatly enhancing the efficacy and adaptability of pharmaceutical formulations. Transdermal gel formulations are examples of nonnanoemulsion formulations compared to nanoemulsion-based formulations that show a significant improvement in drug bioavailability. Nanoemulsions, distinguished by their nanoscale droplets, offer increased solubility for medications with low water solubility and a large interfacial area for drug dissolution. Higher drug-loading capacities as a result of this benefit enable the delivery of a larger variety of therapeutic agents. Nanoemulsions can increase medication penetration through the skin in the case of transdermal gels, resulting in a quicker beginning of action and better therapeutic results [26]. Additionally, nanoemulsions have outstanding stability, which shields drugs from deterioration and extends the shelf life of pharmaceuticals. This characteristic is particularly important when discussing transdermal gels since consistent medication administration depends on the formulation’s ability to hold up over time.

The differences between transdermal gels with and without nanoemulsions highlight the advantages of the latter. Gels made from nanoemulsions have a larger drug-loading capacity, better skin penetration, and a lower risk of skin irritation. They make it possible to precisely regulate the kinetics of medication release, which improves patient compliance and therapeutic efficiency. Additionally, nanoemulsions can be administered orally, intravenously, or topically with great flexibility. Due to their adaptability, they are useful in a variety of medication delivery applications and can meet various patient demands.

Table 1 Various excipients widely used in nanoemulsion formulations.

| Brand name/chemical definition (HLB value) | Components | Traders/manufacturers |

|---|---|---|

| Tween 20 (T20)/PEG-20 sorbitan monolaurate (16.7) | Emulsifier | Altas/ICI |

| Tween 60 (T60)/polysorbate 60 (14) | Emulsifier | Altas/ICI |

| Tween 65 (T65)/PEG-20 sorbitan tristearate (11) | Emulsifier | Altas/ICI |

| Tween 80 (T80)/PEG-20 sorbitan monooleate (15) | Coemulsifier | Altas/ICI |

| Span 20 (S20)/sorbitan monolaurate (8.6) | Emulsifier | Altas/ICI |

| Span 60 (S60)/sorbitan monostearate 4.7 | Coemulsifier | Altas/ICI |

| Span80 (S80)/sorbitan monooleate (4.3) | Coemulsifier | Altas/ICI |

| Brij-30/PEG-4 lauryl ether (9.7) | Emulsifier | Altas/ICI |

| Arlasolve DMI/Di-methyl isosorbide- | Coemulsifier | Altas/ICI |

| Capmul MCM-C8/glyceryl caprylate (5-6) | Emulsifier | ABITEC |

| Lecithin/L-a-phosphatidylcholine (4–9) | Emulsifier | Alfa Aesar |

| Cerex ELS 250/PEG-25 hydrogenated castor oil (11) | Emulsifier | Auschem SpA |

| Akoline MCM/caprylic/capric glycerides (5-6) | Coemulsifier | Aarhuskarlshamn |

| Cremophor-EL, cremophor-ELP/ PEG-35 castor oil (12–14) | Emulsifier | BASF |

| Cremophor RH40/PEG-35 hydrogenated castor oil (13) | Emulsifier | BASF |

| Pluronic L44/block copolymer of ethylene oxide and propylene oxide (12–18) | Coemulsifier | BASF |

| Lutrol F 68/polaxomer 188 (29) | Coemulsifier | BASF |

| Cremophor RH 40/polyoxyl 40 hydrogenated castor oil (13) | Emulsifier | BASF |

| SLS/sodium lauryl sulfate (40) | Coemulsifier | Canadian Alcolac Ltd. |

| Carbitol/diethylene glycol monoethyl ether- | Coemulsifier | Dow chemicals |

| TPGS/(Tocophersolan, D--tocopheryl PEG-1000 succinate) (13) | Emulsifier | Eastman |

| Labrafil M 2125 CS/PEG-6 corn oil (4) | Emulsifier | Gattefosse |

| Labrafil M1944CS/PEG-6 apricot kernel oil (4) | Emulsifier | Gattefosse |

| Labrasol/PEG-8 caprylic/capric glycerides (14) | Emulsifier | Gattefosse |

| Labrafac CM 10/PEG-8 caprylic/capric glycerides (>10) | Emulsifier | Gattefosse |

| Labrafil WL 2609 BS/PEG-8 corn oil (6-7) | Emulsifier | Gattefosse |

| Peceol glyceryl monooleate (3-4) | Emulsifier | Gattefosse |

| Plurol oleique CC 497 caprol® 6G20 hodag PGO-62/ polyglyceryl-6 dioleate (6) | Coemulsifier | Gattefosse Abitec Co Calgene |

| Lauroglycol 90/propylene glycol monolaurate (5) | Coemulsifier | Gattefosse |

| Lauroglycol FCC/propylene glycol monolaurate (4) | Coemulsifier | Gattefosse |

| Transcutol P/diethylene glycol mono ethyl ether- | Coemulsifier | Gattefosse |

| Labrafil 1944/PEG-6 apricot kernel oil (4) | Coemulsifier | Gattefosse |

| HCO-40/polyoxyethylene hydrogenated castor oil 40 (13) | Emulsifier | Nikkol |

| HCO-60/PEG-60 hydrogenated castor oil (14) | Coemulsifier | Nikkol |

| Emulphor El-620/ethoxylated castor oil (12–15) | Emulsifier | Rhodia |

Download the full article as PDF here Nanoemulsion: An Emerging Novel Technology for Improving the Bioavailability of Drugs

or read it here

Preeti, Sharda Sambhakar, Rohit Malik, Saurabh Bhatia, Ahmed Al Harrasi, Chanchal Rani, Renu Saharan, Suresh Kumar, Geeta, Renu Sehrawat, “Nanoemulsion: An Emerging Novel Technology for Improving the Bioavailability of Drugs”, Scientifica, vol. 2023, Article ID 6640103, 25 pages, 2023. https://doi.org/10.1155/2023/6640103